ACPNUMEN, um jogador renomado na indústria de eletrônicos, se especializa em fornecer capacitores de alta qualidade que atendem a diversos setores, incluindo tecnologia de comunicação. Nossos capacitores de ponta desempenham um papel essencial em garantir a transmissão contínua e a força de sinal inabalável nas redes de telecomunicações aceleradas de hoje. Como a espinha dorsal desses sistemas, os capacitores da ACPNUMEN garantem confiabilidade e eficiência, tornando-os a escolha preferida para empresas que buscam se manter à frente no competitivo cenário de telecomunicações.

Com foco em inovação e qualidade, os capacitores ACPNUMEN se destacam em eletrônica automotiva e aplicações de controle industrial também. Eles são projetados para suportar condições extremas, garantindo desempenho estável em vários ambientes. No campo dos circuitos digitais, nossos capacitores oferecem precisão incomparável, permitindo processamento mais rápido e melhoria no desempenho geral do sistema. Para uma empresa que prospera em atender às demandas da indústria, a ACPNUMEN é seu parceiro ideal para todas as necessidades de capacitores.

Quando se trata de capacitores, a ACPNUMEN se tornou uma marca popular e confiável no mercado de componentes eletrônicos. Nós personalizamos capacitores de alta qualidade para comunicação, equipamentos de telecomunicação, eletrônica automotiva, controle industrial e aplicações de circuitos digitais. O foco na qualidade e confiabilidade dos capacitores ACPNUMEN os tornou a escolha preferida entre engenheiros em todo o mundo.

Na ACPNUMEN, temos orgulho de ter uma ampla gama de capacitores que podem atender a várias necessidades da indústria. Nossos capacitores são projetados para garantir comunicações eficientes, especialmente por meio de sua capacidade de desempenhar exemplarmente. Para fins de filtragem de alta frequência ou acoplamento de sinal, estes oferecem soluções robustas que melhoram a eficiência geral do sistema. Com nossa rigorosa adesão aos procedimentos de garantia de qualidade, temos uma garantia eficaz de que cada capacitor fabricado atende aos mais altos padrões possíveis, pois isso torna a ACPNUMEN um dos nomes mais confiáveis na indústria de eletrônicos.

Os capacitores são indispensáveis para várias indústrias, como comunicação, equipamentos de telecomunicação, eletrônicos automotivos, controle industrial e circuitos digitais no mundo da tecnologia em rápida mudança. Atualmente, a ACPNUMEN está liderando entre as empresas que fornecem capacitores de alta qualidade que podem atender às diversas necessidades dos clientes dessas áreas.

Sendo uma marca reconhecida neste setor de negócios, estamos cientes da importância de fabricar capacitores que sejam confiáveis, eficazes e duradouros, utilizando tecnologia progressiva. Mantemos constantemente o ritmo com as invenções mais atualizadas e as implementamos em nossos produtos. Assim, oferecemos capacitores que têm desempenho excepcional para que qualquer cliente possa realizar seus objetivos de forma eficaz.

ACPNUMEN possui várias características únicas que a distinguem dos concorrentes, mas a qualidade é uma delas. Para fabricar nossos capacitores, utilizamos apenas matérias-primas de primeira classe, permitindo que operem nas condições mais severas possíveis. Além disso, cada capacitor é submetido a um rigoroso processo de teste que envolve processos de verificação realizados para garantir a conformidade com os padrões estabelecidos de qualidade. Nosso objetivo final é garantir relacionamentos de longo prazo com clientes que confiam em nós para capacitores de boa qualidade.

Várias indústrias requerem capacitores de alta qualidade; é aqui que a ACPNUMEN entra. Nossa prioridade é garantir que ofereçamos soluções personalizadas de capacitores para os mercados de comunicação, equipamentos de telecomunicação, eletrônicos automotivos, controle industrial e circuitos digitais. Ao longo dos anos, a empresa construiu uma reputação como um fornecedor confiável de capacitores devido à vasta experiência na indústria.

Os capacitores da ACPNUMEN são projetados para apresentar desempenho superior enquanto mantêm qualidade consistente. Apreciamos que para sua aplicação específica você precise do tipo certo de capacitor, portanto, nossa equipe dedicada colabora de perto com os clientes para que possam elaborar respostas personalizadas. Nos esforçamos para oferecer aos nossos clientes produtos que tenham a capacidade de suportar condições operacionais severas. Este compromisso com a perfeição nos ajudou a ganhar a confiança de nossos clientes que sempre voltam para mais.

ACPNUMEN se destaca entre os fabricantes de capacitores de alta qualidade nos campos dinâmicos de comunicação e sistemas de controle industrial. Esses dispositivos são feitos com a máxima precisão para evitar quaisquer desvios, mesmo em condições adversas. Os capacitores ACPNUMEN desempenham um papel importante nesta área por meio de seu foco na melhoria da eficácia operacional e confiabilidade para equipamentos de comunicação, telecomunicações, eletrônica automotiva e circuitos digitais.

No entanto, não pode haver compromisso com a qualidade dos capacitores utilizados em equipamentos de comunicação e telecomunicações. Para os capacitores ACPNUMEN, eles são projetados para garantir que haja transmissão de sinal estável, baixa corrente de fuga, bem como alta retenção de capacitância, para que os usuários experimentem conexões suaves e obtenham o melhor desempenho. Eles fornecem desempenho consistente em diferentes condições de operação, seja em um smartphone avançado ou em uma infraestrutura de telecomunicações complexa.

Por outro lado, ao lidar com eletrônicos automotivos ou no campo de controle industrial, os capacitores ACP NUMEN são projetados para serem confiáveis e duráveis o suficiente para suportar condições tão severas como as encontradas nos pisos de fabricação. Nossos produtos foram desenvolvidos para atender a temperaturas extremas, vibrações e flutuações de tensão conforme exigido pelos padrões da indústria. Isso reduzirá o tempo de inatividade resultante de níveis de eficiência aumentados, bem como aumentará a segurança, o que afetará positivamente a produtividade, caso os fabricantes escolham esses capacitores em particular.

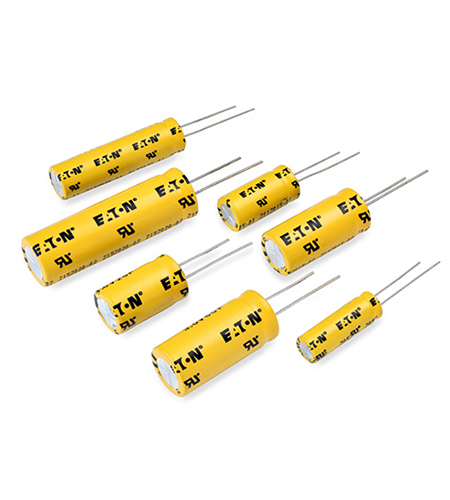

ACPNUMEN Fundada em 1998, o grupo é um prestador de serviços abrangente focado em produtos eletrônicos de potência. Ele assinou um acordo de cooperação com a Eaton Bussmann, uma das 500 maiores empresas da Fortune nos EUA! No momento, a empresa se concentra em comunicação, equipamentos de telecomunicações, eletrônica automotiva, controle industrial, circuitos digitais e outros campos. Desde a sua criação, sempre acreditamos que: A qualidade é a base da sobrevivência da empresa, a reputação faz o desenvolvimento continuar, a inovação torna a empresa brilhante.

Obtivemos muitos direitos de agência de marcas famosas, como Eaton Bussmann, On-Bright, Littelfuse, Conquer, Sino fuse, Allen-Bradley, Aupo, Wago, Sanyou e outros.

Temos 26 anos de experiência em proteção de circuitos.

Serviço 24 horas por dia, resposta rápida em até 2 horas.

Produtos de marca original 100%, garantia total de qualidade, certificações completas.

Um capacitor eletrônico é um componente eletrônico que armazena e libera energia elétrica. Ele é usado em vários circuitos eletrônicos para estabilizar a voltagem, filtrar ruídos e armazenar energia temporariamente.

Capacitores eletrônicos são amplamente utilizados em indústrias como comunicação, equipamentos de telecomunicação, eletrônica automotiva, controle industrial e circuitos digitais. Eles são empregados em dispositivos e circuitos eletrônicos nesses campos.

Capacitores eletrônicos podem ser usados para regulação de voltagem até certo ponto. Eles podem ajudar a estabilizar os níveis de voltagem suavizando flutuações e reduzindo ruídos em circuitos eletrônicos. No entanto, dispositivos dedicados à regulação de voltagem podem ser necessários para uma regulação precisa.

Sim, capacitores eletrônicos podem ser usados para armazenamento temporário de energia em circuitos eletrônicos. Eles podem armazenar energia e liberá-la rapidamente quando necessário, mas sua capacidade de armazenamento de energia é tipicamente menor em comparação com dispositivos dedicados ao armazenamento de energia.

2024 © Shanghai King-Tech Electronic Co., Ltd. Política de Privacidade