La ACPNUMEN, înțelegem rolul critic al protecției fiabile a circuitelor în industriile de înaltă tehnologie de astăzi. Expertiza noastră constă în a răspunde nevoilor sectorului de comunicații, echipamente de telecomunicații și electronice auto. Când vine vorba de protejarea circuitelor electrice sensibile, siguranțele ceramice se remarcă ca o alegere de top. ACPNUMEN oferă soluții premium de siguranțe ceramice care asigură performanță optimă și siguranță chiar și în cele mai exigente condiții. Aceste siguranțe sunt concepute pentru a rezista cerințelor riguroase ale circuitelor digitale și sistemelor de control industrial, oferind un răspuns rapid și precis la situațiile de supracurent.

În lumea electronicelor în continuă evoluție, ACPNUMEN rămâne în frunte prin livrarea tehnologiei de siguranțe ceramice de vârf. Produsele noastre sunt special concepute pentru industrii care necesită precizie și reziliență, cum ar fi automotive și telecomunicații. Cu stabilitatea lor termică excelentă și caracteristicile de reacție rapidă, siguranțele noastre ceramice joacă un rol esențial în prevenirea deteriorării echipamentelor valoroase. Aveți încredere în ACPNUMEN pentru o protecție a circuitelor fără egal care menține operațiunile dumneavoastră în funcțiune lin și în siguranță.

ACPNUMEN activează în domeniile comunicațiilor, telecomunicațiilor, electronicii auto, controlului industrial și circuitelor digitale, oferind soluții inovatoare pentru o gamă largă de clienți. Activitatea noastră principală constă în fabricarea fuzibilelor ceramice de bună calitate, concepute pentru a asigura o funcționare sigură cu performanțe optime. Acest articol va discuta câteva caracteristici și avantaje ale fuzibilelor noastre ceramice.

Fusele ceramice sunt componente vitale în multe sisteme electrice și electronice. Acestea întrerup curentul circuitului dacă depășește o valoare sigură, protejând astfel împotriva suprasarcinilor electrice. ACPNUMEN se concentrează pe fabricarea fuselelor ceramice de înaltă calitate care depășesc fusele convenționale din sticlă. Legăturile noastre fuzibile sunt fabricate din ceramici avansate care prezintă o rezistență dielectrica ridicată, precum și rezistență la termocicluri, permițând astfel utilizarea lor continuă în condiții de serviciu severe pentru perioade lungi.

ACPNUMEN, un important producător de fituri ceramice, prezintă soluţii sofisticate concepute pentru industriile de înaltă tehnologie. Siguriile ACPNUMEN sunt precise și fiabile în ceea ce privește nevoile de comunicare, dispozitivele de telecomunicații, electronica auto, sistemele de control industrial, printre alte aplicații de circuite digitale care necesită soluții de inginerie de precizie.

Unele dintre caracteristicile siguranței ceramice ACPNUMEN sunt: Capacitatea de a proiecta siguranțe realizate la comandă care pot fi potrivite cu cerințele tehnice specifice sau cu condițiile de mediu. Ar trebui să aibă stabilitate și durabilitate la temperaturi ridicate, având astfel o

Angajamentul companiei pentru excelență este demonstrat pe parcursul întregii sale operațiuni, începând cu selecția materialelor până la testarea lor riguroasă, apoi oferind sprijinul necesar chiar și după finalizarea vânzărilor, astfel încât acestea să poată oferi o asigurare de siguranță în timpul utilizării acestor echip

Pentru dispozitivele de comunicaţii şi telecomunicaţii, nimic nu este mai important decât fiabilitatea. ACPNUMEN un jucător renumit din industrie prezintă fituri ceramice excelente care promit performanţe nonstop în astfel de aplicaţii critice. Întrerupătoarele noastre de ceramică sunt cunoscute pentru rezistenţa şi continuitatea lor în întreaga lume printre ingineri şi designeri.

Proiectat pentru a rezista utilizării grele în multe aplicații: Gadgeturile de comunicare au criterii stricte, conform ACPNUMEN. Ele se asigură că fiturile noastre pot tolera cele mai grele condiţii care ar putea provoca alte defecte în timp ce încă de a efectua în mod fiabil în cazul în care acestea ar trebui să funcţioneze bine în alte aparate. Aceste dispozitive protejează circuitele de telecomunicații delicate datorită dimensiunii lor mici, împreună cu o rezistență ridicată la șocuri termice, făcându-le astfel suficient de puternice chiar și pentru utilizarea grea, cum ar fi protecția electronicii auto, necesită atât de multă compactitate, al

Varietatea de aplicații: Pe lângă faptul că sunt utilizate pe scară largă în instrumentele de comunicare în sine, ceramica fabricată de ACPNUMEN găsește aplicații extinse în întreaga; de la sistemele electronice automobile până la controalele industriale până la căile de semnal digital sunt atinse printre multe al

Fiabilitatea sigiliilor este foarte importantă în domeniul comunicațiilor, echipamentelor de telecomunicații, electronicii auto și controlului industrial. Siguriile ceramice Acpnumen sunt fabricate cu precizie pentru a oferi performanțe ridicate și durabilitate. Aceste sigilii protejează componentele electronice sensibile de deteriorare, oferind o barieră esențială împotriva condițiilor de suprasufluență. Întreprinderile pot fi sigure că sistemele lor sunt bine protejate atunci când folosesc fituri ceramice Acpnumen.

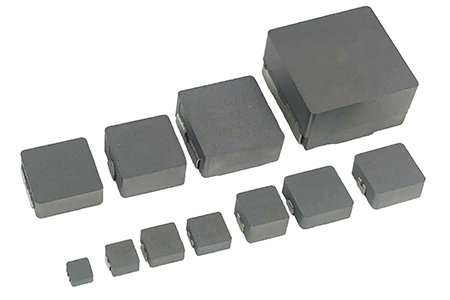

Acpnumen oferă mai multe aplicații pentru produsele sale de siguranță din ceramică. Ele servesc multe industrii diferite, inclusiv cele care se ocupă de circuite digitale. Acest lucru le facilitează asimilarea în diferite sisteme, deoarece vine într-o varietate de dimensiuni și configurații. Eficienţa şi fiabilitatea sigiliilor noastre ceramice atestă angajamentul nostru pentru excelenţă. În plus, produsele noastre sunt supuse unor teste riguroase pentru a îndeplini cerințele stricte din domeniul comunicațiilor, telecomunicațiilor, industriei auto și al controlului industrial, cărora le furnizăm produsele noastre.

ACPNUMEN Fondat în 1998, grupul este un furnizor de servicii complete, cu accent pe produsele electronice de putere. A semnat un acord de cooperare cu Eaton Bussmnann, una dintre cele mai importante 500 de companii din SUA! În prezent, compania se concentrează pe comunicații, echipamente de telecomunicații, electronice auto, control industrial, circuite digitale și alte domenii. De la înfiinţarea sa, am crezut întotdeauna că: Calitatea este baza supravieţuirii întreprinderii, reputaţia face dezvoltarea continuă, inovaţia face întreprinderea strălucitoare.

Am obținut multe drepturi de reprezentanță a unor mărci famosoase cum ar fi Eaton Bussmann, On-Bright, Littelfuse, Conquer, Sino fuse, Allen-Bradley, Aupo, Wago, Sanyou și altele.

Avem 26 de ani de experiență în protecția circuitelor.

Serviciu 24 de ore pe zi, răspuns rapid în 2 ore.

Produse de 100% mărci originale, garanție de 100% calitate, toate certificările necesare.

26

Apr

26

Apr

26

AprFuseele ceramice sunt dispozitive de siguranță electrice fabricate din material ceramic care oferă protecție împotriva supracurentului sau a scurtcircuitelor în circuitele electrice.

Sigurile ceramice găsesc aplicații în diverse industrii, cum ar fi comunicațiile, echipamentele de telecomunicații, electronicele auto, controlul industrial și circuitele digitale. Ele sunt folosite pentru a proteja circuitele electrice în aceste câmpuri.

Siguriile ceramice sunt concepute pentru a oferi o protecţie fiabilă circuitelor electrice. Cu toate acestea, fiabilitatea unui sigiliu depinde şi de instalarea corectă şi de respectarea normelor de siguranţă electrică.

Siguriile din ceramică pot fi achiziționate de la distribuitori sau comercianți cu amănuntul autorizați. Se recomandă să se exploreze opţiuni precum Eaton Bussmann, o companie din Fortune 500, care oferă o gamă largă de produse electrice.

2024 © Shanghai King-Tech Electronic Co., Ltd. Politica de confidențialitate