ในด้านอุปกรณ์สื่อสารและโทรคมนาคม ACPNUMEN ยืนเป็นจุดหมายของนวัตกรรมและความน่าเชื่อถือ ที่สําคัญที่สุดในกิจกรรมของเราคือความเข้าใจอย่างลึกซึ้ง เกี่ยวกับบทบาทสําคัญที่เครื่องตัดวงจรเล่น ในการปกป้องระบบอิเล็กทรอนิกส์ที่ซับซ้อน เครื่องตัดวงจรไม่ใช่แค่สวิตช์ง่ายๆ แต่เป็นอุปกรณ์ป้องกัน ที่ตรวจจับความผิดปกติในกระแสไฟฟ้า และตัดวงจรให้เร็ว เพื่อป้องกันความเสียหาย ในฐานะเป็นบริษัทชั้นนํา ACPNUMEN รับประกันว่าสินค้าของเราถูกจัดให้พร้อมกับเครื่องตัดวงจรชั้นนํา ซึ่งเป็นสิ่งจําเป็นในการรักษาความสมบูรณ์แบบของทางการสื่อสารและโทรคมนาคมของเรา

ในโลกของอิเล็กทรอนิกส์ ACPNUMEN เป็นผู้ปกป้องวงจรที่โดดเด่นผ่านเบรกเกอร์วงจรชั้นนำที่ถูกออกแบบมาเพื่อปกป้องการดำเนินงานที่สำคัญในพื้นที่ต่างๆ เช่น การสื่อสาร โทรคมนาคม อิเล็กทรอนิกส์ในยานยนต์ วงจรดิจิทัล และการควบคุมอุตสาหกรรม เบรกเกอร์วงจรของเรารับประกันความต่อเนื่องและการให้บริการที่ไม่หยุดชะงัก

ฟังก์ชันการทำงานเป็นสิ่งสำคัญอันดับแรกที่ครอบงำโลก ดังนั้นความสำคัญของเบรกเกอร์วงจร ACPNUMEN ที่ปกป้องอิเล็กทรอนิกส์ที่ซับซ้อนและละเอียดอ่อนจากกระแสเกินที่ทำให้เกิดความเสียหาย เบรกเกอร์วงจรแต่ละตัวถูกออกแบบโดยใช้เทคโนโลยีล่าสุดเพื่อให้สามารถตอบสนองได้อย่างรวดเร็วโดยไม่ส่งผลกระทบต่อการทำงานของระบบอื่นที่เชื่อมต่ออยู่ ตั้งแต่การปกป้องความสมบูรณ์ของอิเล็กทรอนิกส์ในยานยนต์หรือการป้องกันความล้มเหลวที่ร้ายแรงของเครือข่ายโทรคมนาคม ACPNUMEN เป็นทางเลือกที่สมบูรณ์แบบสำหรับนักออกแบบและวิศวกรทั่วโลก

อุปกรณ์การสื่อสารและโทรคมนาคมพึ่งพาอุปกรณ์ต่างๆ เช่น เบรกเกอร์ไฟฟ้า ในกรณีนี้ ACPNUMEN เข้าใจว่ามันสำคัญเพียงใดในการรับประกันความต่อเนื่องและความปลอดภัยของระบบเหล่านี้ ด้วยเบรกเกอร์ไฟฟ้าของเรา คุณสามารถมั่นใจได้ว่าระบบของคุณจะได้รับการปกป้องจากปัญหาไฟฟ้าหรือการโหลดเกินที่อาจเกิดขึ้น พวกมันถูกออกแบบด้วยเทคโนโลยีขั้นสูงและทำจากวัสดุคุณภาพที่ทำให้สามารถนำไฟฟ้าได้และควบคุมอุณหภูมิได้ดี ดังนั้นจึงสามารถใช้ในระบบโทรคมนาคมและอื่นๆ ได้

สุดท้ายนี้ ACPNUMEN ยังเชี่ยวชาญด้านอิเล็กทรอนิกส์ในยานยนต์ ความซับซ้อนของยานพาหนะสมัยใหม่รวมถึงการพึ่งพาชิ้นส่วนอิเล็กทรอนิกส์ที่เพิ่มขึ้นทำให้จำเป็นต้องให้ความสำคัญกับความปลอดภัยและความเชื่อถือได้เป็นอันดับแรก ดังนั้น เบรกเกอร์ของเราจึงป้องกันพัลส์พลังงานที่อาจทำลายระบบที่ป้องกันบุคคลจากสถานการณ์อันตรายรวมถึงความผิดปกติทางไฟฟ้าอื่นๆ ที่อาจเกิดขึ้น

ACPNUMEN เป็นแบรนด์ส่วนประกอบไฟฟ้าที่ครองตำแหน่งหนึ่งในแบรนด์ชั้นนำมาหลายปีแล้ว และยินดีที่จะเปิดเผยช่วงผลิตภัณฑ์เบรกเกอร์วงจรทั้งหมดที่ออกแบบมาเพื่อตอบสนองความต้องการที่หลากหลายของอุตสาหกรรมในปัจจุบัน ในฐานะผู้ผลิตเบรกเกอร์วงจรชั้นนำ ACPNUMEN มุ่งมั่นที่จะนำเสนอทางออกที่มีคุณภาพซึ่งเพิ่มความปลอดภัย ประสิทธิภาพ และความน่าเชื่อถือในระบบไฟฟ้าหลายประเภท

เบรกเกอร์วงจรของ ACPNUMEN ถูกออกแบบมาโดยเฉพาะเพื่อให้การป้องกันที่เหนือชั้นต่อการลัดวงจรและการโหลดเกินซึ่งส่งผลให้มีการรักษาความปลอดภัยของอุปกรณ์และบุคลากร ความมุ่งมั่นของบริษัทต่อคุณภาพสามารถเห็นได้ในผลิตภัณฑ์ทั้งหมดของพวกเขาตั้งแต่การออกแบบที่แข็งแกร่งไปจนถึงกระบวนการผลิตที่แม่นยำ ด้วยเบรกเกอร์วงจรของ ACPNUMEN ผู้ใช้ไม่ต้องกังวลเกี่ยวกับระบบไฟฟ้าของตนเลย

นอกจากนี้ ACPNUMEN ยังมีบริการลูกค้าที่โดดเด่นและการสนับสนุนควบคู่ไปกับสินค้าคุณภาพสูงของตน สายด่วนเทคนิค คำตอบที่ปรับแต่งได้ และการดูแลหลังการขายทั้งหมดดำเนินการโดยผู้เชี่ยวชาญของบริษัท ไม่ว่าคุณจะต้องการเบรกเกอร์ทั่วไปหรือเบรกเกอร์ที่ปรับแต่งได้ เชื่อมั่นใน ACPNUMEN สำหรับความปลอดภัยและความเชื่อถือได้ของโครงสร้างพื้นฐานด้านไฟฟ้าของคุณ

ในการป้องกันไฟฟ้า ACPNUMEN เป็นผู้จัดจำหน่ายที่โดดเด่นของเบรกเกอร์วงจรที่ให้บริการอุตสาหกรรมต่างๆ เบรกเกอร์วงจรคุณภาพสูงของเราเหมาะสำหรับการสื่อสาร อุปกรณ์โทรคมนาคม อิเล็กทรอนิกส์ในยานยนต์ การควบคุมอุตสาหกรรม และวงจDIGITAL ซึ่งช่วยให้การดำเนินงานไม่หยุดชะงักและเพิ่มความปลอดภัยให้กับทรัพย์สินของธุรกิจของคุณ

เบรกเกอร์วงจรของ ACPNUMEN เป็นทางเลือกที่ดีที่สุดในการปกป้องระบบไฟฟ้าของคุณ พวกเขาได้รับการออกแบบอย่างแม่นยำและใส่ใจอย่างมากเพื่อให้สามารถทนต่อสภาพที่ต้องการทั้งในเครือข่ายการสื่อสารหรือการใช้งานในยานยนต์ จุดประสงค์ของอุปกรณ์เหล่านี้คือการตัดการทำงานในกรณีที่มีความผิดปกติเกิดขึ้นในกระแสไฟฟ้า ดังนั้นจึงปกป้องวงจรจากการเสียหาย เมื่อคุณเลือกเบรกเกอร์วงจรของบริษัทของเรา คุณกำลังทำการลงทุนเชิงกลยุทธ์ในด้านการดำเนินงานระยะยาวและประสิทธิภาพของธุรกิจของคุณ

ACPNUMEN รับรู้ว่าอุตสาหกรรมสมัยใหม่ต้องการผลิตภัณฑ์ของตนเพื่อให้ทำงานได้ดีในเรื่องของเบรกเกอร์วงจร ผู้เชี่ยวชาญของเรามุ่งมั่นที่จะสร้างสรรค์นวัตกรรมและปรับปรุงผลิตภัณฑ์ของเราอย่างต่อเนื่องเพื่อให้ตอบสนองความต้องการที่เปลี่ยนแปลงของลูกค้า ไม่ว่าคุณจะทำงานในอุตสาหกรรมโทรคมนาคมหรือมีระบบที่ซับซ้อนที่ควบคุมอุตสาหกรรม เบรกเกอร์วงจรของเราช่วยให้มีประสิทธิภาพที่ดียิ่งขึ้นโดยมีพื้นที่การติดตั้งที่น้อยลงและการรวมเข้าที่ง่าย เบรกเกอร์วงจรของ ACPNUMEN จะทำให้การทำงานราบรื่นตลอดเวลา จึงป้องกันการทำลายและการหยุดทำงานของสิ่งของที่มีค่า

ACPNUMEN ก่อตั้งขึ้นในปี 1998 กลุ่มนี้เป็นผู้ให้บริการที่ครบวงจรที่มุ่งเน้นผลิตภัณฑ์อิเล็กทรอนิกส์พลังงาน ได้ลงนามในข้อตกลงความร่วมมือกับ Eaton Bussmann หนึ่งในบริษัทที่ติดอันดับ Fortune 500 ในสหรัฐอเมริกา! ขณะนี้บริษัทมุ่งเน้นไปที่การสื่อสาร อุปกรณ์โทรคมนาคม อิเล็กทรอนิกส์ในยานยนต์ การควบคุมอุตสาหกรรม วงจรดิจิตอล และสาขาอื่น ๆ ตั้งแต่ก่อตั้ง เราเชื่อเสมอว่า: คุณภาพคือพื้นฐานของการอยู่รอดขององค์กร ชื่อเสียงทำให้การพัฒนาต่อเนื่อง นวัตกรรมทำให้องค์กรโดดเด่น.

เราได้รับสิทธิ์ตัวแทนของแบรนด์ชื่อดังหลายแห่ง เช่น Eaton Bussmann, On-Bright, Littelfuse, Conquer, Sino fuse, Allen-Bradley, Aupo, Wago, Sanyou และอื่นๆ

เรามีประสบการณ์ 26 ปีในด้านการป้องกันวงจร

ให้บริการตลอด 24 ชั่วโมง ตอบกลับอย่างรวดเร็วภายใน 2 ชั่วโมง

สินค้าแบรนด์แท้ 100% การรับประกันคุณภาพ 100% มีใบรับรองครบถ้วน

26

Apr

26

Apr

26

Aprเบรกเกอร์ไฟฟ้าเป็นอุปกรณ์สวิตช์ไฟฟ้าที่ออกแบบมาเพื่อหยุดการไหลของกระแสไฟฟ้าในวงจรโดยอัตโนมัติเมื่อมันตรวจพบการโหลดเกินหรือการลัดวงจร

เบรกเกอร์ไฟฟ้าถูกใช้ในอุตสาหกรรมต่างๆ เช่น การสื่อสาร อุปกรณ์โทรคมนาคม อิเล็กทรอนิกส์ในยานยนต์ การควบคุมอุตสาหกรรม และวงจรดิจิทัล พวกเขาให้การป้องกันวงจรไฟฟ้าในสาขาเหล่านี้

ใช่, เบรกเกอร์สามารถรีเซ็ตได้หลังจากที่มันตัดการทำงาน เมื่อปัญหาได้รับการแก้ไขแล้ว เบรกเกอร์สามารถรีเซ็ตด้วยมือโดยการสลับกลับไปที่ตำแหน่ง "เปิด" อย่างไรก็ตาม, สิ่งสำคัญคือต้องระบุและจัดการกับสาเหตุที่แท้จริงของการตัดการทำงานเพื่อป้องกันปัญหาที่เกิดขึ้นซ้ำ

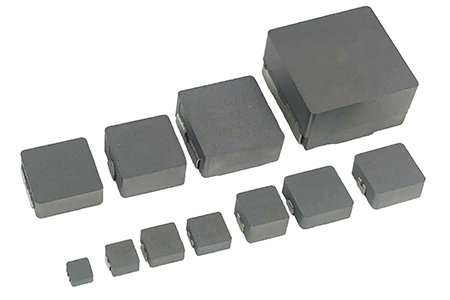

เบรกเกอร์มีหลายประเภทและขนาดเพื่อรองรับระบบไฟฟ้าที่แตกต่างกัน สิ่งสำคัญคือต้องเลือกเบรกเกอร์ที่ตรงกับแรงดันไฟฟ้า, การจัดอันดับกระแส, และข้อกำหนดอื่น ๆ ที่จำเป็นสำหรับการใช้งานเฉพาะของคุณ

2024 © บริษัท เชียงไคเช็ค อิเล็กทรอนิกส์ จำกัด นโยบายความเป็นส่วนตัว