У сфері електронних схем не можна переоцінити важливість запобіжників. Вони служать важливим захисним пунктом від надтоглих обставин, запобігаючи можливим пошкодженням або пожежам. ACPNUMEN, бренд, що є синонімом досконалості в електронній промисловості, спеціалізується на виробництві високоякісних керамічних предохражувачів, які обслуговують різноманітні сектори. З акцентом на комунікації, телекомунікаційне обладнання, автомобільну електроніку, промислове управління та цифрові схеми, керамічні предохражувачі ACPNUMEN розроблені для надійних характеристик в найбільш вимогливих умовах.

Керамічні предохражувачі ACPNUMEN спроектовані, щоб витримувати високі температури і жорсткі умови, що робить їх ідеальним вибором для сектора комунікаційного та телекомунікаційного обладнання. Ці запобіжники забезпечують, щоб чутливі комунікаційні пристрої працювали в межах їх безпечного потоку, запобігаючи перевантаженню та потенційним перебоям у роботі. Завдяки компактним розмірам і швидкому часу реагування керамічні запобіжники ACPNUMEN забезпечують ефективний захист без шкоди для продуктивності. Вибираючи ACPNUMEN, клієнтам гарантується найвищий рівень безпеки та надійності їхньої комунікаційної інфраструктури.

У промисловому контролю безпека є найважливішим фактором. ACPNUMEN, яка є добре відомою компанією в цьому секторі, виробляє передові керамічні запобіжники, розроблені для задоволення дуже жорстких вимог. Наші керамічні предохражувачі захищають критичні комунікаційні, телекомунікаційні та автомобільні електронні системи від надтоку та короткого закликання. Хоча вони мають швидкий час реагування і відмінну теплову стійкість, наші керамічні предохражувачі ACPNUMEN забезпечують надійну безпеку від можливих пошкоджень, які призводять до втрати ефективності через зниження загальної ефективності обладнання.

Тривалість і висока температурна стійкість наших керамічних предохражувачів роблять їх унікальними. Ці особливості роблять їх ідеальними для використання в цифрових схемах та промислових застосуваннях, де панувають жорсткі умови. Ми гарантуємо повну відповідальність за якість, перевіряючи кожен шматок керамічного фіксу для однорідності продуктивності та довготривалості використання в різних галузях промисловості, що вимагає від нас виробляти замовлені фіксу за певними вимогами.

Тому важливо вибрати правильного партнера з синтезу, якщо ви хочете захистити свої електронні активи. Ми не просто пропонуємо стандартні продукти, але ми працюємо з вами, щоб краще зрозуміти ваші проблеми в ACPNUMEN. Наша команда фахівців завжди готова надати консультаційну службу, розробку та виробництво керамічних розв'язків, які перевищують ваші очікування. Різниця відчувається через ACPNUMEN, тому що інновації поєднуються з надійностю, щоб було безпечніше завтра завдяки кращому промисловому електроніці.

Якісні предохражувачі дуже важливі для безпеки та надійності комунікацій, а також електричних систем. Середні, низькі та високі напруги керамічні розв'язки ACPNUMEN займають центральну позицію. Ці запобіжники відомі своєю точністю і довговічністю, будучи зроблені за найвищими стандартами для використання в екстремальних електричних умовах, які можуть бути досить непередбачуваними.

Використовуючи складні технології, наша кераміка була розроблена для різних застосувань, особливо там, де є потреба захистити критичні електричні системи, такі як автомобільна електроніка, промислове управління серед інших цифрових схем, які також можуть їх вимагати. Ми пишаємося нашими світовим виробничим процесом в ACPNUMEN, який гарантує, що кожен вироблений запобіжник відповідає найкращим параметрам безпеки, і все одно виконує свою функцію ефективно без будь-яких збоїв; це досягається шляхом швидкого переривання аномального потоку струму, щоб не тільки заощадити,

У сучасному світі, де люди вимагають ефективних методів комунікації, які також є безпечними, ACPNUMEN постійно демонструє свій інноваційний характер у поєднанні з відмінним рівнем обслуговування клієнтів. [1] Це означає, що ці типи кераміки можуть бути застосовані в багатьох секторах завдяки їх адаптивності, а Маючи висококваліфікованих інженерів плюс враховуючи потреби клієнтів перш за все, що дозволило нам залишатися вперед як номер один постачальник для різних підприємств, які шукають безпечні надійні рішення, що стосуються різних типів або марок керамічних предохражувачів, що продаються нами; це не просто зупиняється

ACPNUMEN працює в сферах комунікацій, телекомунікацій, автомобільної електроніки, промислових керувань та цифрових схем, надаючи інноваційні рішення для широкого кола клієнтів. Наша основна діяльність полягає в виробництві якісних керамічних предохражувачів, які розроблені для забезпечення безпечної роботи з оптимальною продуктивністю. У цій статті розглянуто деякі особливості і переваги наших керамічних розгалужувачів.

Керамічні предохражувачі є важливими компонентами багатьох електричних і електронних систем. Вони запускають струму, якщо вона перевищує безпечне значення, захищаючи від будь-яких електричних перевантажень. ACPNUMEN зосереджена на виробництві високоякісних керамічних предохражувачів, які перевершують звичайні скляні. Наші з'єднання зроблені з передової кераміки, що демонструє високу диелектричну міцність, а також стійкість до термошок, що дозволяє їх безперервне використання в жорстких умовах служби протягом тривалого періоду часу.

Незмінність запобіжників дуже важлива в області зв'язку, телекомунікаційного обладнання, автомобільної електроніки та промислового управління. Керамічні предохражувачі Acpnumen виготовлені з точністю, щоб забезпечити високу ефективність і довговічність. Ці запобіжники захищають чутливі електронні компоненти від пошкодження, забезпечуючи необхідний бар'єр проти перетоку. Підприємства можуть бути впевнені, що їхні системи добре захищені, коли вони використовують керамічні предохражувачі Acpnumen.

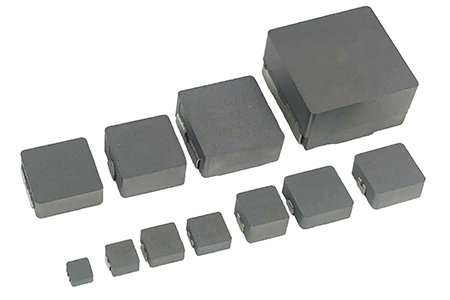

Acpnumen надає більше одного застосування для своїх керамічних засобів для запобіжників. Вони обслуговують багато різних галузей, включаючи ті, які займаються цифровими схемами. Це полегшує їх асиміляцію в різні системи, оскільки вони мають різні розміри і конфігурації. Ефективність і надійність наших керамічних предохражувачів свідчать про нашу відданість до досконалості. Крім того, наші продукти проходять суворі випробування, щоб відповідати суворим вимогам у галузі зв'язку, телекомунікацій, автомобільної промисловості та промислового управління, яким ми постачаємо наші товари.

ACPNUMEN Заснована в 1998 році, група є комплексним постачальником послуг, що спеціалізується на електронічних продуктах. Вона підписала угоду про співпрацю з компанією Eaton Bussmnann, однією з 500 найбільших компаній Fortune в США! В даний час компанія зосереджена на комунікації, телекомунікаційному обладнання, автомобільній електроніці, промисловому управлінні, цифровій схемі та інших областях. З моменту заснування ми завжди вважали, що якість є основою виживання підприємства, репутація робить розвиток безперервним, інновації роблять підприємство блискучим.

Ми отримали багато агентських прав від відомих брендів, таких як Eaton Bussmann, On-Bright, Littelfuse, Conquer, Sino fuse, Allen-Bradley, Aupo, Wago, Sanyou і ін.

У нас є 26-річний досвід у галузі захисту електричних кол.

Обслуговування 24 години на добу, швидка відповідь протягом 2 годин.

100% оригінальні продукти брендів, 100% гарантія якості, повні сертифікації.

26

Apr

26

Apr

26

AprКерамічний запобіжник - це електричне пристрої безпеки, виготовлене з керамічного матеріалу, яке забезпечує захист від перетоку або короткого заклику в електричних схемах.

Керамічні запрівники застосовуються в різних галузях промисловості, таких як комунікація, телекомунікаційне обладнання, автомобільна електроніка, промислове управління та цифрові схеми. Вони використовуються для захисту електричних схем у цих областях.

Керамічні предохражувачі призначені для забезпечення надійного захисту електричних схем. Однак надійність запобіжника залежить також від правильної установки і дотримання правил безпеки.

Керамічні предохражувачі можна придбати у авторизованих дистриб'юторів або роздрібних торговців. Рекомендується вивчити такі варіанти, як Eaton Bussmann, компанія з списку Fortune 500, яка пропонує широкий спектр електротехнічних продуктів.

2024 © Shanghai King-Tech Electronic Co., Ltd. Політика конфіденційності