در زمینه حفاظت از مدار الکتریکی، ACPNUMEN به عنوان یک ارائه دهنده برجسته از راه حل های جامع برجسته می شود. به عنوان شرکتی که در ارتباطات، تجهیزات مخابراتی، الکترونیک خودرو، کنترل صنعتی و مدارهای دیجیتال تخصص دارد، ما اهمیت تکنولوژی فیوز قابل اعتماد را درک می کنیم. اینجاست که همکاری ما با فیوز های Bussmann وارد بازی می شود، اطمینان از عملکرد و ایمنی مطلوب در کاربردهای مختلف.

با ACPNUMEN، مشتریان می توانند مطمئن باشند که آنها فیوز های Bussmann برتر را دریافت می کنند که بر اساس نیازهای خاص صنعت خود طراحی شده اند. تجهیزات مخابراتی و مخابراتی پیشرفته ما نیاز به حفاظت دقیق و کارآمد از فیوز برای جلوگیری از اضافه بار مدار و خطرات آتش سوزی بالقوه دارند. با ادغام فیوز های بوسمن در محصولات ما، ما یک راه حل قوی و قابل اعتماد را تضمین می کنیم که اولویت عملکرد و ایمنی را دارد.

فیوز های بوسمن بخشی مهم از سیستم های الکتریکی هستند زیرا آنها ایمنی را همراه با کارایی در توزیع و حفاظت از برق تضمین می کنند. ACPNUMEN اهمیت این فناوری را در بخش های مختلف به عنوان یک ارائه دهنده عمده راه حل های الکتریکی می شناسد. به دلیل خلاقیت و قابلیت اطمینان خود، ACPNUMEN تنها با محصولات با کیفیت بالا که همیشه توسط آزمایشات مختلف برای اثبات صداقت خود قبل از عرضه به بازار برای استفاده توسط مصرف کنندگان که ممکن است آنها را در صنایع مورد نیاز خود در هر بخش مورد نیاز داشته باشند، معامله می کند.

فيوز هاي Bussmann ACPNUMEN مي توانند در برابر بار زيادي الکتريکي يا مدار کوتاه محافظت کنند، بيشتر از هر برند ديگري که امروزه در فروشگاه ها موجود است. این نوع فیوز ها جریان جریان را بلافاصله در صورت بروز نقص متوقف می کنند و در نتیجه آسیب تجهیزات و آسیب های پرسنلی ناشی از چنین حوادث را به حداقل می رسانند بنابراین آنها بسیار ایمن محسوب می شوند اگرچه دانستن اینکه آنها واقعاً چقدر خوب کار می کنند بدون آزمایش آنها را آسان نیست اما ما یک چیز را می دانیم ، شرکت در کیفیت در طول

در حفاظت از مدار الکتریکی، ACPNUMEN یک ارائه دهنده شناخته شده با کیفیت بالا از راه حل های فیوز Bussmann سطح بالا است. تعهد ما به کیفیت شامل تجهیزات ارتباطی، الکترونیک خودرو، کنترل صنعتی و زمینه های مدار دیجیتال در میان دیگران است. فیوز بوسمن یک قطعه اصلی ایمنی الکتریکی است که عملکرد راحت دستگاه ها را در این مناطق حیاتی تضمین می کند. ما در ACPNUMEN از قابلیت اطمینان و عملکرد قدردانی می کنیم و بنابراین انواع مختلفی از فیوز های Bussman را بسته به نیازهای خاص مشتریان مختلف ارائه می دهیم.

برای مدارهای پیچیده ای که در ارتباطات مخابراتی و همچنین الکترونیک خودرو یافت می شوند، داشتن فیوز های بوسمن نمی تواند بیش از حد تأکید شود. توسط ACPNUMEN طراحی شده تا از هر گونه حالت اضافه شدن جریان که می تواند منجر به خرابی فاجعه بار تجهیزات شود جلوگیری کند. محافظ های ساکت ما مانند محافظان عمل می کنند که هر گونه جریان اضافی را از رسیدن به سیستم های الکترونیکی حساس جلوگیری می کنند. با همکاری با ما، شرکت ها با کیفیت و قابلیت اعتماد ارتباط برقرار می کنند و در عین حال سرمایه گذاری در فناوری ارزشمند را حفظ می کنند.

در زمینه انتخاب مناسبترین فوزهای Bussmann در محیطهای سریع مثل کنترلهای صنعتی یا مدارهای دیجیتال، هیچ اشتباهی قابل پذیرش نیست. با دانش فراوان به دست آمده از تجربه، ACPNUMEN میتواند بهترین فوز را برای مختلفترین کاربردهای این بخش پیشنهاد دهد. در شرکت ما، متخصصانی وجود دارند که درک عمیقی از چالشهای مواجه شده توسط صنایع دارند و بنابراین همیشه آماده ارائه راهحلهای سفارشی هستند که نیازهای خاص را برآورده میکند. با استفاده از محصولات برند Bussman در چنین شرایطی، شرکتهای مختلف هرگز اشتباه نخواهند کرد، زیرا قابلیت اعتماد آن تحت شرایط استثنایی آزمایش شده است، جایی که تنها چند برند میتوانند به اندازه کافی عملکرد خوبی داشته باشند، چه برسد به اینکه فراتر از انتظارات کاربران طی سالها موفق شوند.

فیوز های بوسمن یک حوزه است که در آن ACPNUMEN، متخصص عناصر الکتریکی، برجسته است. این فیوز های با کارایی بالا هستند که برای بخش هایی مانند صنعت مخابرات، تجهیزات ارتباطی و تلمیتیک و الکترونیک خودرو طراحی شده اند و اطمینان از ایمنی و قابلیت اطمینان کامل دارند. این به ما اجازه می دهد تا اطمینان حاصل کنیم که شما تعادل مناسب بین حفاظت و کارایی برای مدارهای دیجیتال و سیستم های کنترل صنعتی خود را به دست آورید، با استفاده از دانش عمیق ما از فیوز های بوسمن.

اکپنومن به عنوان یکی از بهترین شرکت های صنعت خود اهمیت فیوز های بوسمن را در کنترل خطرات افزایش قدرت می داند. خط جامع ما شامل آمپر های مختلف است که قطعات الکترونیکی شکننده شما را از شکستن محافظت می کند. ما فقط محصولات واقعی بسمن را می خریم چون ما کیفیت را بالاتر از هر چیز دیگری اولویت می دهیم تا حتی در محیط های صنعتی سخت عملکردی عالی داشته باشند.

وقتی نوبت به انتخاب یک فیوز Bussmann مناسب برای برنامه شما می رسد، ACPNUMEN دارای تخصصی است که می توانید به آن اعتماد کنید. بنابراین، تیم ما از مهندسان ماهر در راه حل های سفارشی تخصص دارد و بنابراین اطمینان حاصل می کند که شما انتخاب های آگاهانه ای را در مورد آنچه که متناسب با نیازهای خاص شما است، انجام می دهید. بنابراین چه ارتقاء زیرساخت های مخابراتی و چه حفاظت از الکترونیک خودرو، خطوط مختلف ACPNUMEN نیازهای شما را در مورد فیوز های Bussman برآورده می کنند و در نتیجه انتظارات ناشی از آن را فراتر می برند.

در دنیای امروز که به سرعت در حال تغییر است، ارتباطات، مخابرات، الکترونیک خودرو، کنترل صنعتی و سایر صنایع به طور فزاینده ای به راه حل های قابل اعتماد فیوزینگ وابسته هستند که به عملکرد مناسب سیستم های آنها کمک می کنند. ACPNUMEN نامی است که در این صنعت شناخته شده است و می تواند راه حل های بی نظیر فیوز Bussmann را ارائه دهد که به این بخش های مختلف خدمت می کند. این پست وبلاگ نگاهی دقیق تر به چگونگی ترکیب بوسمن ACPNUMEN با پیشرفت های تکنولوژیکی برق و زیرساخت های مدرن دارد.

مدارهای دیجیتال با گذشت زمان پیچیده تر شده اند، بنابراین نیاز به فیوز های بوسمن وجود دارد که می توانند جریان های بالا را اداره کنند و همچنین محافظت از شارژ را ارائه دهند. توانایی فیوز های ACPNUMENS Bussman برای حفظ یکپارچگی سیستم در شرایط شدید باعث شده است که آنها در میان متخصصان مخابرات که اغلب با سیستم های مختلف به طور همزمان در مسافت های طولانی یا در ساختمان ها کار می کنند، شهرت داشته باشند. به همین دلیل بسیاری از کارشناسان در این زمینه آنها را بهترین انتخاب می دانند. این برند همچنین به شدت بر نوآوری و کیفیت تمرکز دارد، بنابراین تولید ارتباطات بی سیم آن باعث افزایش انتقال سیگنال می شود تا آنها به اجزای ضروری در هر شبکه ای طراحی شده در حال حاضر تبدیل شوند.

وقتی صحبت از الکترونیک خودرو می شود، استانداردهای ایمنی که توسط صنعت خودرو تعیین شده است، چیزی کمتر از عملکرد برتر از هر قطعه ای که در آن استفاده می شود، از جمله آنهایی که مربوط به حفاظت الکتریکی مانند فیوز طراحی شده توسط ACPNUMEN تحت نام تجاری Bussman است. این دستگاه ها باید قادر به ارائه محافظ قوی در برابر شارژ شوند و در نتیجه عملکرد قابل اطمینان را در تمام قطعات مختلف خودرو از خودروهای الکتریکی (EV) تا سیستم های پیشرفته کمک راننده (ADAS) تضمین کنند. علاوه بر این، مقاومت در برابر دمای شدید در حالی که هنوز هم سطح کارایی مورد نیاز در طول دوره عملیات را حفظ می کند، در محدوده این شرکت قرار دارد تا هیچ کس به دلیل گرم شدن ناشی از اشعه های شدید خورشید که به طور مستقیم در روزهای گرم در تجهیزات نصب شده در داشبورد قرار می گیرد، زمانی که AC از کار می رود، حتی

ACPNUMEN در سال 1998 تأسیس شد، این گروه یک ارائهدهنده خدمات جامع است که بر روی محصولات الکترونیکی قدرت تمرکز دارد. این شرکت توافقنامه همکاری با Eaton Bussmann، یکی از شرکتهای برتر Fortune 500 در ایالات متحده امضا کرده است! در حال حاضر، این شرکت بر روی ارتباطات، تجهیزات مخابراتی، الکترونیک خودرو، کنترل صنعتی، مدارهای دیجیتال و سایر زمینهها تمرکز دارد. از زمان تأسیس، ما همیشه بر این باور بودهایم که: کیفیت اساس بقای شرکت است، شهرت باعث ادامه توسعه میشود، و نوآوری شرکت را درخشان میکند.

ما حق نمایندگی بسیاری از برندهای معروف را به دست آوردهایم، مانند Eaton Bussmann، On-Bright، Littelfuse، Conquer، Sino fuse، Allen-Bradley، Aupo، Wago، Sanyou و غیره.

ما ۲۶ سال سابقه در حوزه محافظت مدار داریم.

خدمات ۲۴ ساعته، پاسخ سریع در حدود ۲ ساعت.

محصولات ۱۰۰٪ اصیل برند، ۱۰۰٪ تضمین کیفیت، مدارک کامل.

26

Apr

26

Apr

26

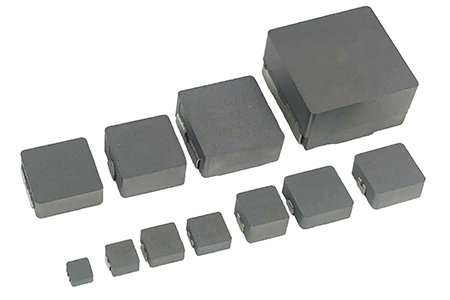

Aprفیوز بوسمن یک نوع دستگاه ایمنی الکتریکی است که برای محافظت از مدارهای الکتریکی از شرایط جریان بیش از حد یا مدار کوتاه طراحی شده است. این محصول توسط شرکت ایتون بوسمن، یک شرکت Fortune 500 در ایالات متحده تولید می شود.

فیوز های بوسمن معمولاً در صنایع مختلف مانند ارتباطات، تجهیزات مخابراتی، الکترونیک خودرو، کنترل صنعتی و مدارهای دیجیتال استفاده می شوند. اونا از مدار الکتريکي در اين رشته ها محافظت ميکنن

وقتی جریان جریان از طریق یک مدار از مقدار نامی فیوز فراتر رود، فیوز ذوب یا منفجر می شود، جریان الکتریکی را قطع می کند و مدار را از آسیب محافظت می کند. این کار به جلوگیری از آتش سوزی و خرابی تجهیزات کمک می کند.

فیوز های بوسمن توسط شرکت ایتون بوسمن ساخته می شوند، یک شرکت معتبر که به تولید محصولات الکتریکی با کیفیت بالا شناخته شده است. اما، قابلیت اطمینان فیوز ها نیز به نصب صحیح و رعایت دستورالعمل های ایمنی الکتریکی بستگی دارد.

بله، وقتی یک فیوز Bussmann به دلیل جریان بیش از حد یا مدار کوتاه منفجر یا ذوب شود، باید جایگزین شود. مهم است که یک فیوز جایگزین با ولتاژ و جریان مشابه فیوز اصلی انتخاب شود.

2024 © شرکت الکترونیک کینگ-تک شانگهای. سیاست حریم خصوصی