شرکت ACPNUMEN، یک شرکت پیشگام در صنعت الکترونیک، در پیشروی توسعه تکنولوژی خازن بوده است. تخصص ما در بخش های مختلف از جمله ارتباطات، تجهیزات مخابراتی، الکترونیک خودرو، کنترل صنعتی، مدار دیجیتال و موارد دیگر گسترش می یابد. ما متعهد به ارائه راه حل های خازن با کیفیت بالا هستیم که نیازهای متنوع مشتریان ما را برآورده می کند.

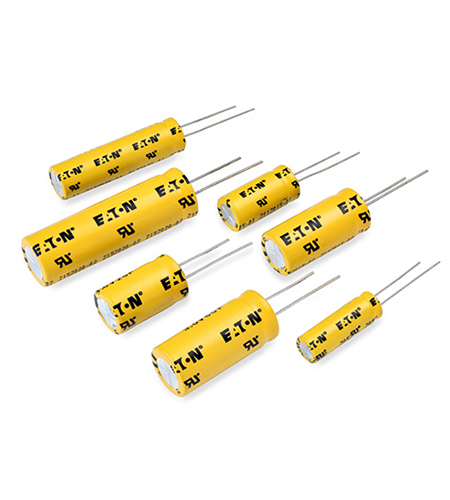

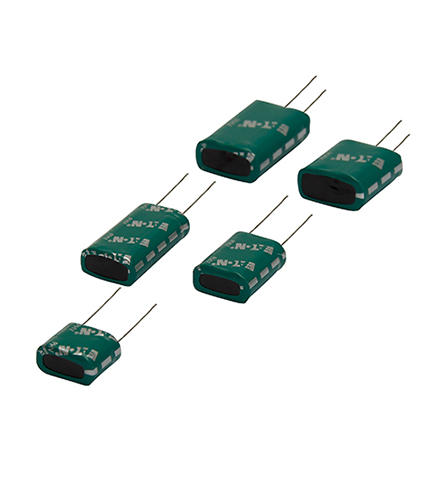

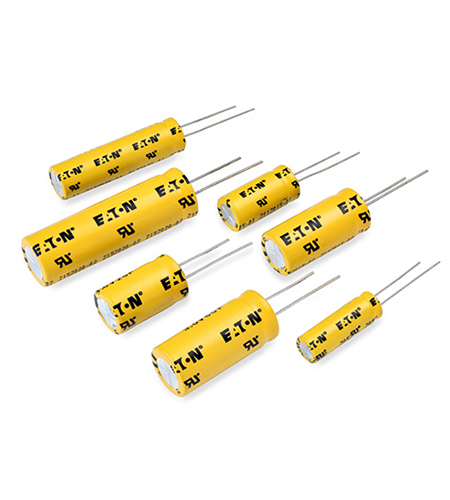

در زمینه تجهیزات ارتباطات و مخابرات، خازن ها نقش مهمی در تضمین عملکرد و قابلیت اطمینان بهینه ای دارند. در ACPNUMEN، ما این اهمیت را درک می کنیم و فناوری های پیشرفته خازن را توسعه داده ایم که نیازهای سختگیرانه این صنایع را برآورده می کند. خازن های ما ثبات عالی، تراکم انرژی بالا و مقاومت درجه حرارت عالی را ارائه می دهند، که آنها را برای استفاده در دستگاه های ارتباطی مانند تلفن های همراه، ایستگاه های پایه و تجهیزات رادیویی ایده آل می کند.

وقتی صحبت از خازن ها می شود، ACPNUMEN به یک برند محبوب و قابل اعتماد در بازار قطعات الکترونیکی تبدیل شده است. ما کانسیداتورهای با کیفیت بالا را برای ارتباطات، تجهیزات مخابراتی، الکترونیک خودرو، کنترل صنعتی و کاربردهای مدار دیجیتال طراحی کرده ایم. تمرکز بر کیفیت و قابلیت اطمینان کانسپاتورهای ACPNUMEN باعث شده که آنها انتخاب مورد علاقه مهندسان در سراسر جهان باشند.

در ACPNUMEN، ما افتخار می کنیم که طیف گسترده ای از خازن ها را داریم که می توانند نیازهای مختلف صنعت را برآورده کنند. خازن هاي ما براي تامين ارتباطات کارآمد به خصوص از طريق توانايي عملکرد مثالي آنها ساخته شده اند. برای فیلتر کردن فرکانس بالا یا اهداف اتصال سیگنال، این راه حل های قوی را ارائه می دهند که کارایی کلی سیستم را بهبود می بخشد. با رعایت سختگیرانه روش های تضمین کیفیت، ما تضمین موثر داریم که هر خازن تولید شده با بالاترین استانداردهای ممکن مطابقت دارد زیرا این باعث می شود ACPNUMEN یکی از معتبرترین نام های صنعت الکترونیک باشد.

اکپنونمن در میان تولید کنندگان خازن های با کیفیت بالا در زمینه های سریع ارتباطات و سیستم های کنترل صنعتی برجسته است. اين دستگاه ها با دقت بيشتري ساخته شده اند تا از انحرافات در شرایط سخت اجتناب کنند. خازن های ACPNUMEN با تمرکز بر بهبود اثربخشی عملیاتی و قابلیت اطمینان برای ارتباطات، تجهیزات مخابراتی، الکترونیک خودرو و مدارهای دیجیتال نقش مهمی در این زمینه ایفا می کنند.

با این حال، هیچ سازش در مورد کیفیت خازن های مورد استفاده در تجهیزات ارتباطات و مخابرات وجود ندارد. برای خازن های ACPNUMEN ، آنها برای اطمینان از انتقال سیگنال پایدار ، جریان نشت کم و همچنین حفظ ظرفیت بالا ساخته شده اند تا کاربران از اتصال صاف و بهترین عملکرد برخوردار شوند. آنها عملکرد ثابت را در شرایط مختلف عملیاتی فراهم می کنند، چه یک تلفن هوشمند پیشرفته باشد یا یک زیرساخت پیچیده مخابراتی.

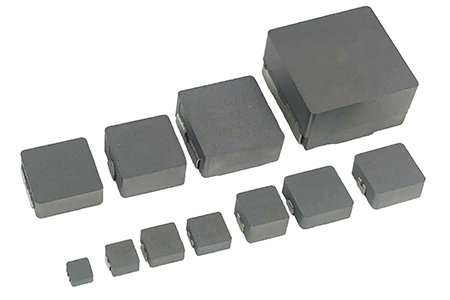

در مقابل، در مورد الکترونیک خودرو یا کنترل صنعتی، خازن های ACP NUMEN به اندازه کافی قابل اعتماد و با دوام طراحی شده اند تا در شرایط سختی مانند تولیدات موجود باشند. محصولات ما برای رفع دماهای شدید، لرزش ها و نوسانات ولتاژ به عنوان مورد نیاز استانداردهای صنعت توسعه یافته اند. این باعث کاهش زمان توقف ناشی از افزایش سطح بهره وری و همچنین افزایش امنیت می شود که در صورت انتخاب این خازن های خاص، بر بهره وری تاثیر مثبت خواهد گذاشت.

خازن ها برای صنایع مختلف مانند ارتباطات، تجهیزات مخابراتی، الکترونیک خودرو، کنترل صنعتی و مدارهای دیجیتال در دنیای فناوری در حال تغییر سریع ضروری هستند. در حال حاضر، ACPNUMEN در میان شرکت های تامین کننده خازن های با کیفیت بالا که می توانند نیازهای متنوع مشتریان را از این مناطق برآورده کنند، پیشرو است.

به عنوان یک برند شناخته شده در این حوزه کسب و کار ما از اهمیت ساخت خازن هایی که قابل اعتماد، موثر و طولانی مدت با استفاده از تکنولوژی پیشرفته است آگاه هستیم. ما دائما با آخرین اختراعات در حال پیشرفت هستیم و آنها را در محصولات خود پیاده سازی می کنیم. بنابراین ما خازن هایی را ارائه می دهیم که عملکردی برجسته برای هر مشتری برای تحقق اهداف خود به طور موثر دارند.

ACPNUMEN دارای چندین ویژگی منحصر به فرد است که آن را از رقبای خود متمایز می کند اما کیفیت یکی از آنها است. برای تولید خازن های ما ما فقط از مواد خام از بالاترین درجه استفاده می کنیم بنابراین آنها را قادر می سازد در سخت ترین شرایط ممکن کار کنند. علاوه بر این، هر خازن تحت یک فرآیند آزمایش دقیق قرار می گیرد که شامل فرآیندهای تأیید انجام شده برای تضمین انطباق با استانداردهای تعیین شده در مورد کیفیت است. هدف نهایی ما تضمین روابط بلند مدت با مشتریان است که برای خازن های با کیفیت خوب به ما اعتماد می کنند.

صنایع زیادی نیاز به خازن های با کیفیت بالا دارند؛ این جایی است که ACPNUMEN وارد عمل می شود. اولویت ما این است که اطمینان حاصل کنیم که ما راه حل های خلبان شخصی را برای ارتباطات، تجهیزات مخابراتی، الکترونیک خودرو، کنترل صنعتی و بازارهای مدار دیجیتال ارائه می دهیم. در طول سالها این شرکت به دلیل تجربه گسترده در صنعت، شهرت خود را به عنوان یک تامین کننده قابل اعتماد از خازن ها ایجاد کرده است.

خازن هاي ACPNUMEN براي ارائه عملکرد برتر در حال حفظ کیفیت ثابت طراحی شده اند. ما درک می کنیم که برای برنامه خاص شما به نوع مناسب خازن نیاز دارید بنابراین تیم اختصاصی ما با مشتریان همکاری نزدیک دارد تا بتوانند راه حل های سفارشی را ایجاد کنند. ما تلاش می کنیم که به مشتریانمان محصولاتی را ارائه دهیم که توانایی تحمل شرایط سخت عملیاتی را داشته باشند. این تعهد به کمال به ما کمک کرده تا اعتماد مشتریانمان را که همیشه برای بیشتر باز می گردند، به دست آوریم.

ACPNUMEN در سال 1998 تأسیس شد، این گروه یک ارائهدهنده خدمات جامع است که بر روی محصولات الکترونیکی قدرت تمرکز دارد. این شرکت توافقنامه همکاری با Eaton Bussmann، یکی از شرکتهای برتر Fortune 500 در ایالات متحده امضا کرده است! در حال حاضر، این شرکت بر روی ارتباطات، تجهیزات مخابراتی، الکترونیک خودرو، کنترل صنعتی، مدارهای دیجیتال و سایر زمینهها تمرکز دارد. از زمان تأسیس، ما همیشه بر این باور بودهایم که: کیفیت اساس بقای شرکت است، شهرت باعث ادامه توسعه میشود، و نوآوری شرکت را درخشان میکند.

ما حق نمایندگی بسیاری از برندهای معروف را به دست آوردهایم، مانند Eaton Bussmann، On-Bright، Littelfuse، Conquer، Sino fuse، Allen-Bradley، Aupo، Wago، Sanyou و غیره.

ما ۲۶ سال سابقه در حوزه محافظت مدار داریم.

خدمات ۲۴ ساعته، پاسخ سریع در حدود ۲ ساعت.

محصولات ۱۰۰٪ اصیل برند، ۱۰۰٪ تضمین کیفیت، مدارک کامل.

26

Apr

26

Apr

26

Aprخازن الکترونیک یک قطعه الکترونیکی است که انرژی الکتریکی را ذخیره و آزاد می کند. این در مدارهای مختلف الکترونیکی برای ثبات ولتاژ، فیلتر کردن سر و صدا و ذخیره سازی انرژی به طور موقت استفاده می شود.

خازن های الکترونیک به طور گسترده ای در صنایع مانند ارتباطات، تجهیزات مخابراتی، الکترونیک خودرو، کنترل صنعتی و مدارهای دیجیتال استفاده می شوند. آنها در دستگاه های الکترونیکی و مدارها در این زمینه ها استفاده می شوند.

کانسیداتورهای الکترونیک می توانند تا حدودی برای تنظیم ولتاژ استفاده شوند. آنها می توانند با صاف کردن نوسانات و کاهش سر و صدا در مدارهای الکترونیکی، سطح ولتاژ را پایدار کنند. با این حال، دستگاه های تنظیم ولتاژ اختصاصی ممکن است برای تنظیم دقیق مورد نیاز باشند.

بله، کانسیداتورهای الکترونیک می توانند برای ذخیره سازی موقت انرژی در مدارهای الکترونیکی استفاده شوند. آنها می توانند انرژی را ذخیره کنند و در صورت نیاز به سرعت آن را آزاد کنند، اما ظرفیت آنها برای ذخیره انرژی معمولا در مقایسه با دستگاه های ذخیره سازی انرژی اختصاصی کوچکتر است.

2024 © شرکت الکترونیک کینگ-تک شانگهای. سیاست حریم خصوصی